TKR7200 – ET410 1/10TH 4WD COMPETITION ELECTRIC TRUGGY KIT

Regular price

£308.00

Sale

TKR7200 – ET410 1/10TH 4WD COMPETITION ELECTRIC TRUGGY KIT.

At Tekno RC, we’ve always strived to think outside the box. Rules and standards are great and all, but when it comes to maximum fun and performance, sometimes you just have to do your own thing. For example, it’s only been about 10 years since we pioneered the 1/8th electric buggy class. From there we released the first purpose-built 1/8th electric buggy kit in 2012, and that class is now one of the most popular in the world.

This time though, we didn’t throw out the rulebook entirely as the 1/10th 4wd truck class has been ‘on the books’ for quite some time. Knowing that, we saw an opportunity to introduce a new vehicle that checks all of the right boxes – performance, innovation, durability, and most of all, fun!

With advances in battery and motor technology, as well as design evolution and material properties, it was only a matter of time until a truly viable 1/10th 4wd truck entered the market. We are happy to answer the call and we’ll say without hesitation that this new truck is about the most fun you can have with an RC car.

The ET410 excels on every track surface whether it be clay, carpet, dirt, indoor, or outdoor. That’s not a huge surprise since it’s based on the wildly successful EB410 platform. We designed new suspension arms, shock towers, rear shocks, body mounts, ET48.3 inspired truggy body, and driveline components to push the ET410 out to 1/10th 2wd/4wd truck specs.

All of the innovations from the EB410 buggy are present on the ET410. From the weight-forward chassis layout and superior differential design, to the reverse bellcrank steering system and 13mm big bore shocks, you’ll be immediately familiar with the truck out of the box. This also means that most of the aftermarket parts for the EB410 will be direct replacement options for the ET410.

During testing we found a variety of motors that work well to power the ET410 from standard 2-pole offerings (5.5-10.5T) to 4-pole 540-size SCT motors (4000-5000kv). Don’t be afraid to put tons of power through the ET410 as a newly designed 32 pitch spur gear and thicker driveshafts are more than up to the task. And yes, it’s fully capable of pulling wheelies if you like messing around in the backyard or off the track.

In addition to standard 2.2” truck wheels and tires (AE offset), we thought it necessary to support SCT wheels and tires (Slash offset) as a bolt-on option. So there’s a good chance you already have everything you need in your RC toolbox to get going.

If you already own an EB410, you’ll be happy to know that the parts are 95% compatible with the ET410. This means you won’t need to stock up on a completely new set of spare parts and all of the routine maintenance you’ve become familiar with will apply to the ET410. So if you’re looking for a ‘new’ class to run or just want to have a good time with an awesome RC vehicle, the ET410 will deliver.

ET410 Key Features:

- 95% parts compatibility with the EB410 4WD 1/10th scale buggy.

- Updated 3mm 7075 CNC chassis and revised A and B hinge pin braces.

- 13mm hard anodized threaded shocks with locking spring perches.

- New 32 pitch spur gear for ultimate durability

- 3.5mm shock shafts with revised dual guide x-ring cartridge.

- 7075 CNC machined adjustable hinge pin brace system.

- Three high volume fluid-filled adjustable differentials.

- Lightweight 7075 tapered center driveshafts.

- Quick access to differentials and maintenance friendly layout.

- Captured CVA front and rear driveshafts with heavy duty 6mm stub axles.

- Fully ball raced reverse bellcrank steering system.

- Uses 1/10th AE Offset Stadium Truck or Traxxas Slash Short Course offset wheels.

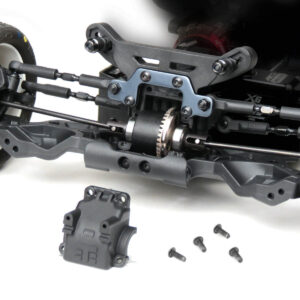

Shaft-Drive and Differentials:

The first decision to be made was how to get power to the wheels. It was an easy decision for us to choose a shaft-drive system over a belt drive system due to the advantages in durability, efficiency, adjustability, and ease of maintenance. Belts can slip or strip under the load of modern brushless motor systems. The increased friction of belts versus shafts/gears wastes energy, reduces runtime, and hinders top speed. A shaft-drive system easily accommodates a center differential, which is critical for adjusting the front/rear power transfer characteristics. Finally, gaining quick access to all three differentials was one of our goals that could have only been met with a shaft-drive system.

On the topic of differentials, we knew it was going to be important to maximize the internal volume of the diff cases. Increased fluid capacity means the differentials can work more efficiently and consistently. We did not see the point of including a center differential and then basically locking it up with 200K or thicker fluid. With the volume maximized, the resulting tuning window is much larger and can be fine-tuned like the differentials used on larger 1/8th scale vehicles. With large truck tires and potential use of 4-pole motors, the drivetrain had to be up to the task of handling more power. To accommodate this, we are introducing a 32 pitch spur gear which will be especially helpful when running outdoors or on tracks with small pebbles.

Driveline:

When it comes to the driveline, achieving maximum efficiency and reducing wear are of utmost importance. Where other vehicles may have a twelve degree or higher compound angle driving the front differential, the ET410 has less than one degree. This reduces friction and increases acceleration out of corners.

We opted for a bearing-captured CVA drive system to transfer power to the wheels. Aside from ensuring you will not lose a drive pin, it allows for larger inner wheel bearings that increase support and durability of the stub axles. The hefty 6mm diameter hardened steel stub axles are surprisingly lightweight due to extra machining operations. In addition, they make use of our existing hex options for the SCT410.3, allowing for different wheel offsets and track width adjustments. Despite the 6mm axle, we maintain the industry standard M4 wheel nut size ensuring replacement parts are easy to find. Center driveshafts are machined from 7075 aluminum and feature the same tapered design found on the EB48.4 1/8th scale buggy.

Reverse Bellcrank Steering System and Front Bulkhead:

The ET410 incorporates the first reverse bellcrank system available for 4WD off-road 1/10th vehicles. It is something 2WD vehicles adopted years ago to help smooth out the steering response and improve consistency through the turns. This was no easy feat, but we achieved it by going all out on the front bulkhead design. It is the single most complex part of the ET410, and possibly of our entire history.

We had many goals to meet with the front bulkhead for us to move forward with the rest of the design. Goals such as quick access to the differentials, the ability to completely seal the gearboxes from the elements, a near straight input to reduce center drive angles, durability to survive hard crashes, and finally, a support structure for the entire steering system. The insanely complex mold was manufactured, tested, and fine-tuned nearly a dozen times to meet the requirements we set forth. On the track, you will immediately notice how smooth and linear the steering is into and out of corners.

|

CNC Machined Components:

Anyone familiar with our products knows we put a premium on how the chassis integrates with the rest of the components. We use aircraft-grade 7075 aluminum and high quality hardened steel alloys for all critical parts such as the chassis, hinge pin braces, motor mount, and driveline components.

The fully machined chassis has been extensively milled out, not only to reduce weight but also to lower the center of gravity for everything installed in the vehicle. The battery, ESC, and RX all sit 1.5mm below the top surface of the chassis. The adjustable hinge pin brace system is a scaled down version of what you would find in our 1/8th scale line of vehicles. It is easy to adjust and tune, and just as durable as you would expect.

The two-piece motor mount system makes gear mesh adjustment and motor removal an easy task. It was designed to produce the lowest center of gravity possible and allows easy access to the center differential without affecting the gear mesh. Lastly, chassis layout places the motor in a location that facilitates the cleanest wiring scheme of any 4WD on the market.

Shocks:

At 13mm, the ET410 shocks are truly big bore. Some might ask, “Why not go with a standard 12mm design?” Our goal was to create an extremely durable and reliable shock system and this meant using 3.5mm shock shafts. But we felt the larger shaft diameter displaced too much oil volume in relation to a 12mm shock body. So in an effort to produce the most consistent shock unit and maintain a high oil capacity, we decided that a 13mm shock body would be best.

Another 30-year-old throwback that still exists in 1/10th scale offroad is the use of E-Clips to secure shock pistons. Not only is this old technology, it also makes changing pistons and working on shocks an unfriendly affair. We did away with this ancient practice by designing a piston and shaft that tightly integrate together. A custom low profile screw secures the assembly and maximizes stroke length.

A locking spring perch design first seen on our 1/8th scale vehicles makes an appearance on the new truggy. This means your springs will stay firmly seated and in action at all times. An extremely compact shock cartridge combined with low profile shock caps provide class-leading suspension travel while simultaneously making use of shorter shock towers for a lower center of gravity. This enables the ET410 to glide over large bumps and land jumps with complete control.

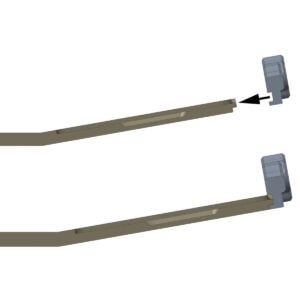

We felt it necessary to include an easier way to adjust droop on a 1/10th scale vehicle. Droop is an important adjustment that affects how the truggy handles. Until now, you had to either screw or unscrew the shock rod end, or worse, take apart the entire shock to add or remove internal limiters. Racers often look for easier adjustments to make rather than go through this rigamarole, even though adjusting droop may yield the most significant improvements on the track. We accomplished this with the simple addition of droop pads on the chassis and droop screws on the arms.

Chassis and Weight Distribution:

To move the weight forward on a smaller 1/10th scale chassis would require a different approach than 1/8th scale since there is not as much chassis area to work with. Considering the battery would utilize the most space, we first needed to determine what battery types to support. With overwhelming acceptance from customers, manufacturers, and the sanctioning bodies, it was a foregone conclusion to settle on a ‘shorty only’ layout for the project. This early decision opened up new possibilities in terms of chassis layout design.

After our team worked through several CAD iterations of the design, we still were not satisfied with where most of the components landed on the chassis. There was more optimization to be made toward the front of the vehicle. We thought if we could just move the bellcranks out of the way, everything could be placed exactly where we wanted. But how?

As noted in part two of our ET410 article series, reverse bellcrank systems have been widely adopted in 2WD vehicles to smooth the steering response and produce a more linear feel. Perhaps it was a natural evolution for 2WD that would never see the light of day in a 4WD shaft driven 1/10th scale vehicle due to spatial and mechanical limitations.

We kept trying though, eventually figuring out a way to squeeze a reverse bellcrank system into the available space around the front bulkhead and center driveshaft. We thought it was crazy at first and the idea was nearly scrapped, but it was the best solution to meet our design goals. Was it even possible to manufacture? Would it be durable enough? Would it perform on the track? We decided to push the envelope and the respective answers were ‘yes’, ‘yes’, and a lot more ‘yes’.

With space at the front end of the chassis finally opened up, it was ready to be populated with electronics as evenly and tightly as possible. The steering servo and battery were placed first, dictating where the motor was to be positioned. After a quick check to make sure all of the popular ESC’s and RX’s would fit the remaining space in front of the motor, the basic layout was complete. All of the components closely neighbor one another allowing for the cleanest and most efficient wiring scheme on the market. This also means you will not have the needless weight of power or control wires running across the chassis.

Our design team then focused on making the user experience as friendly as possible. Installing and removing the battery is straightforward with a single thumb screw. The center differential can be removed with only four screws. There is nothing obstructing access to the steering servo, and the front and rear clips can be removed with a minimum amount of screws for easy cleaning. The rear chassis flex is adjustable using two brace options and there are provisions for raising the rear gearbox to suit different track conditions.

Knowing that this truggy could be subject to even greater impacts than our EB410, our team went about increasing the durability and wear characteristics of the chassis and front end. By making small changes to a few key areas, we were able to improve the durability of the truggy by directly linking the A block with the chassis. With this change, most of the force from an extreme frontal impact is transferred into the chassis, resulting in a tougher front end assembly. Chassis wear characteristics have also improved by slightly reducing the height of the B block, allowing for more material at the chassis kickup.

Taken as a whole, we have produced a simple, yet beautifully balanced layout optimized for modern track surfaces. We believe it is one of the most advanced 1/10th scale 4WD off-road vehicle designs to come along in decades. All this backed by a company committed to vehicle performance, durability, and customer satisfaction.

Chassis

- Modern 1/10th scale 4WD Truggy based on the popular EB410 Buggy.

- Innovative weight forward layout with 1/10th scale rear wing.

- New 3mm CNC 7075 aluminum hard anodized lightened chassis with improved wear characteristics.

- Low COG; Electronics and components sunken into chassis.

- Integrated battery wire guides.

- Ample room for the most popular electronics.

- Popular shorty pack configuration. Better balanced and lighter weight.

- Easy access battery for quick removal and replacement.

- Adjustable chassis brace system for fine tuning rear flex.

Differentials and Drivetrain

- Durable 53t 32 pitch composite spur gear.

- Easy access differentials.

- Three oversized fluid-filled adjustable lightweight diffs.

- Lightened outdrives and diff couplers used throughout.

- Tapered aluminum center driveshafts.

- Angled rear gearbox with large bearings.

- Straight center driveline for maximum efficiency and minimal wear.

- High strength metal ring, pinion, and internal diff gears.

- CVA drive shafts with bearing captured pins.

- Oversized 6mm stub axles with 5mm aluminum nylock wheel nuts.

Shocks

- 13mm big bore shocks with new dual internal shock guides.

- Low COG with compact tower and shock design.

- Super durable 10mm front and 8mm rear composite shock towers.

- Flat/flat piston design (Front – 2 x 1.7 mm + 4 x 0.8 mm, Rear – 2 x 1.8 mm + 4 x 0.8 mm).

- Fully adjustable long travel suspension geometry maximizes stability and traction while providing superior cornering and on-power steering.

- Strong 3.5mm polished steel shock shafts.

- CNC threaded shock bodies and adjustment nuts.

- Composite emulsion shock caps.

- Clamping spring perches.

- Double X-Ring o-rings to provide smooth and consistent damping.

- Optional springs and sway bars are available.

Suspension and Steering

- Compact reverse bellcrank system.

- Bearing supported bellcranks and Ackermann plate.

- Adjustable Ackermann and bump-steer (bump in, zero bump, bump out).

- Adjustable steering stops for precise steering travel settings.

- Adjustable front arm sweep and angle to make the truggy more stable (swept forward), or aggressive (swept back).

- Captured outer front and rear hinge pins.

- Front gullwing arms lowering COG.

- Adjustable CNC 7075 hinge pin braces.

- Updated A and B hinge pin braces to be used with the updated chassis.

- Long rear sway bar for improved consistency.

- 3mm inner and outer hinge pins, polished for smooth action.

- Composite hubs with adjustable camber link position.

- Custom locking kingpin screws.

Motor Mount

- 2-piece CNC aluminum motor mount with precision dual clamping gear mesh adjustment.

- Split center diff mount for easy maintenance.

- Lightweight direct-to-diff mount design.

- Uses standard 32 pitch pinion gears. 1/8th or 5mm bore, depending on motor used.

- Includes integrated fan mount.

Other Features

- High downforce wing with hole guides included.

- Easily adjust anti-squat, rear toe, front arm angle, front arm sweep, roll center, toe, camber, wheelbase, Ackermann, bump steer, suspension geometry out of the box.

- Full set of option parts available.

- Extremely easy to work on with minimal screw count.

- All metric hex hardware.

Specifications

- Length: 393mm (without wing) up to 424mm (with wing).

- Wheelbase: 283-294mm.

- Width: 322-330mm.

- Weight: ~1850-2025g depending upon the equipment used.

- Diff Ratio: F/R – 10/40t, Center – 53t.

- Battery tray dimensions: 96x47x26mm<./li>

- Kit/RTR: Kit.

Needed to Complete

- 2/3 channel radio/transmitter.

- 1/10 scale Buggy or Short Course ESC. *

- 540 size 6.5-8.5 turn or 540 size 4 pole 4000-4600kv motor. *

- High torque steering servo (at least 200oz/in).

- 32 pitch 15 to 19 tooth pinion.

- 2s shorty LiPo battery (at least 5000mAh).

- 1/10th scale Associated offset stadium truck OR Traxxas Slash SC offset wheels and tires.

- CA glue.

- Paint for the body.

Recommended Tools

- Nut drivers 5.5mm (TKR1108) and 7.0mm (TKR1109).

- Hex drivers 1.5mm (TKR1104), 2.0mm (TKR1105) and 2.5mm (TKR1106).

- Hobby knife.

- Needle-nose pliers.

- Shock tool (TKR1115) OR adjustable (Crescent) wrench (for shock assembly).

- 4mm turnbuckle wrench (TKR1103) – 5.5/7.0 two-sided wrench (TKR1119).

- 3mm arm reamer (or #31 drill bit).